Have you ever wondered what makes a Mercedes-AMG so fast? The answer lies inside the Mercedes-AMG Engine Factory. This factory is where speed and precision come together. It’s located in Affalterbach, Germany. Here, the work starts with the engine block. This solid part forms the base of every AMG engine. From there, the magic begins.

A skilled technician builds each engine by hand. AMG follows a special rule called “One Man, One Engine.” This means one person assembles the entire engine alone. That person signs it with pride. Every step follows AMG’s powerful engine philosophy. This idea focuses on care, precision, and quality. Even the smallest part has a big job. Each engine reflects AMG’s love for speed and strength.

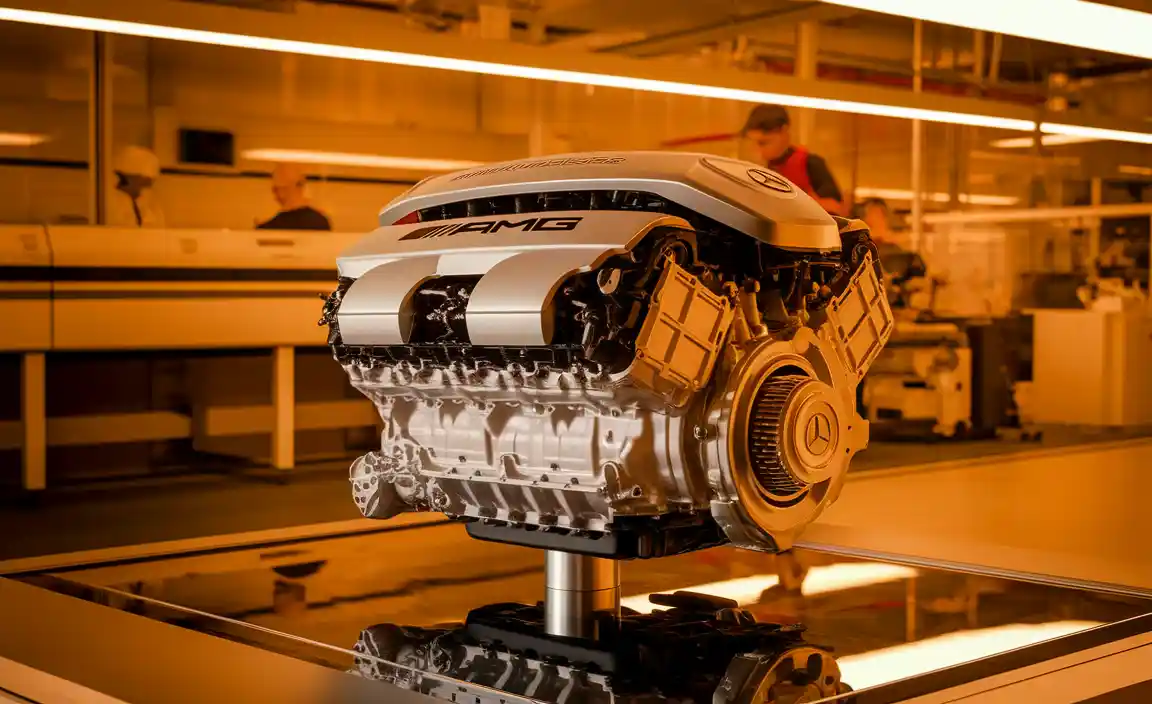

The factory builds famous engines like the M177 V8 and the M139 4-cylinder. These engines power AMG cars with heart-pounding force. This factory doesn’t just build machines. It brings them to life. Want to see how dreams become engines? Let’s take a closer look inside the Mercedes AMG engine factory.

Exploring Inside The Mercedes AMG Engine Factory

History And Evolution Of The Mercedes AMG Engine Factory

The story of the Mercedes-AMG Engine Factory began with two passionate engineers. In 1967, Hans Werner Aufrecht and Erhard Melcher started AMG. They aimed to make V8 engines more powerful. Their goal was simple: build faster, better engines for racing.

AMG quickly gained attention. Their early success came from motorsport. They tuned engines for performance and won races. This work impressed Mercedes-Benz. In 1990, Mercedes-Benz partnered with AMG. This deal marked a big step in performance engineering. AMG now had full access to models with performance technology.

In 2001, AMG opened its engine facility. The factory sits in Affalterbach, Germany. This site builds engines by hand. Each one follows AMG’s “One Man, One Engine” rule.

The factory became a world-class engine site. It makes some of the best racing engines in the industry. Every engine shows AMG’s skill, speed, and precision.

Key Milestones in AMG Factory History

| Year | Milestone |

|---|---|

| 1967 | AMG was founded |

| 1990 | Official partnership with Mercedes-Benz |

| 2001 | Opening of the Mercedes-AMG Engine Factory |

Today, the AMG factory stands at the centre of performance engineering. It combines tradition with cutting-edge tools. Each build reflects decades of racing history. These engines power the world’s top models with performance technology.

Who Builds AMG Engines?

Specially trained AMG technicians build each engine by hand at the Mercedes-AMG factory in Affalterbach, Germany. Under the “One Man, One Engine” philosophy, one expert assembles the entire engine alone. Each engine gets a signed nameplate, showing who built it. This ensures top-level precision and performance.

The Affalterbach Facility

The heart of Mercedes-AMG’s performance lies in Affalterbach, Germany. This small town hosts the world-renowned AMG Engine Manufactory, where powerful engines come to life. The facility is more than just a factory—it’s a hub of precision, passion, and performance engineering. Every engine built here, including the legendary AMG V-8 engine, reflects decades of motorsport heritage and innovation.

Here, the “One Man, One Engine” philosophy guides every step of production. Skilled technicians build each engine by hand, ensuring unmatched attention to detail. This handcrafted method gives each unit a unique character while meeting the highest standards of quality and power.

Advanced Assembly And Engineering Excellence

The Affalterbach plant uses cutting-edge tools and digital systems to streamline the assembly process. Despite high-tech support, the focus stays on manual craftsmanship. Each AMG V-8 engine is hand-assembled with exact measurements and thorough checks. From the engine block to the final seal, engineers follow a strict quality path to ensure peak performance.

Sustainability At The Core

Mercedes-AMG also embraces environmental responsibility. The AMG Engine Manufactory follows green manufacturing practices, reducing emissions and energy use across the facility. Solar panels, heat recovery systems, and eco-friendly logistics all play a part in building engines sustainably. AMG shows that performance and environmental care can work together.

A Symbol Of Performance And Innovation

Affalterbach isn’t just a place—it’s a symbol. It represents what AMG stands for: raw power, refined engineering, and a deep respect for tradition. From here, the roar of the AMG V-8 engine reaches roads and racetracks worldwide. This is where luxury meets speed, and where every engine begins its journey with pride.

The Philosophy Behind AMG Engine Production

The philosophy behind AMG engine production centres on the “One Man, One Engine” craftsmanship approach. At Mercedes-AMG, each engine is meticulously assembled by a single technician who is responsible for every step of the build. This expert then affixes their signature to the engine, symbolising personal accountability and pride in their work.

The process emphasises precision engineering, ensuring that every engine meets the highest standards of strength, reliability, and performance. Attention to detail is critical, as AMG engines are designed to deliver exceptional power, speed, and durability. This dedication to craftsmanship produces unique, high-performance engines that embody AMG’s commitment to excellence.

Where Is The Mercedes-AMG Factory?

The Mercedes-AMG factory is located in Affalterbach, Germany, near Stuttgart. This facility, known as the AMG Engine Manufactory, serves as the heart of AMG’s engine production. Here, skilled technicians hand-assemble powerful engines, including the famous AMG V-8 engines, following the “One Man, One Engine” philosophy. Besides engine building, Affalterbach also houses AMG’s design, development, and management teams, making it the central hub for AMG’s performance engineering and innovation.

What Is The Unique Approach Of AMG Engine Production?

AMG’s unique engine production approach is called “One Man, One Engine.” One technician builds each engine completely by hand. This method ensures top quality and a personal touch. It lets the builder focus on every detail for maximum precision and care.

The Engine Assembly Process

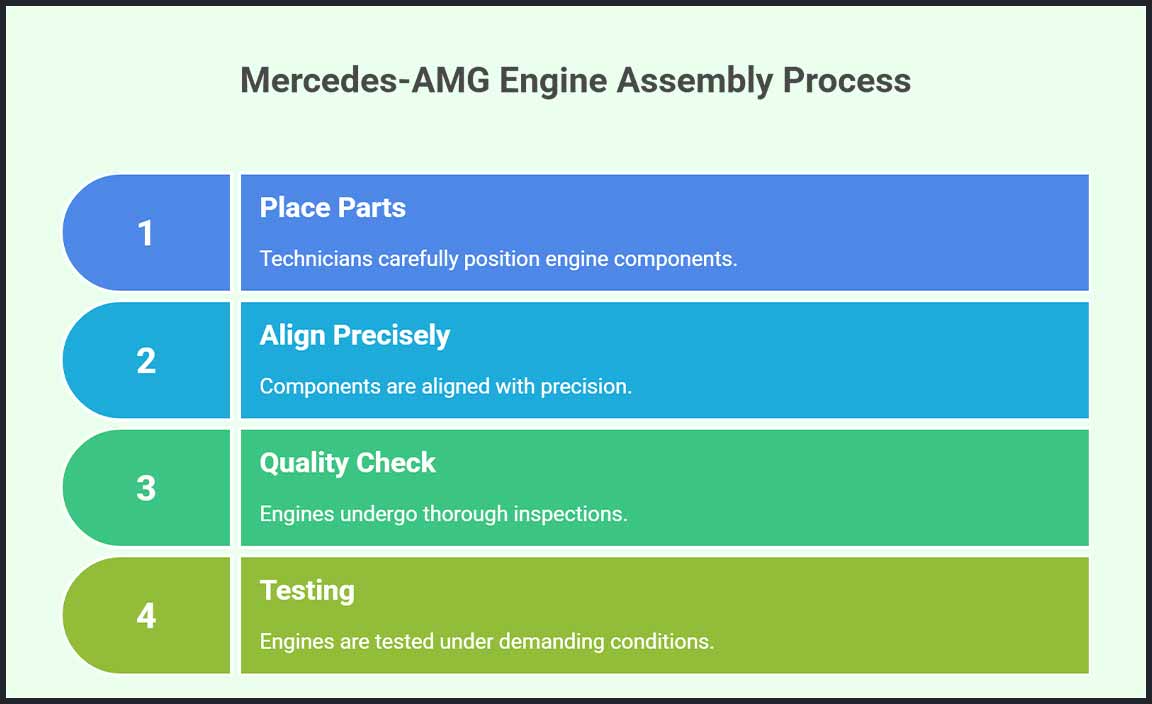

Building a Mercedes-AMG engine is a precise and intricate process. The assembly begins with skilled technicians carefully fitting together hundreds of parts to create powerful and reliable dense engines. These engines often feature an all-new design, combining advanced materials and engineering techniques to deliver exceptional performance. Whether AMG is crafting high-performance gasoline V8s or specialized diesel engines, every step focuses on accuracy and quality.

Technicians follow a detailed, step-by-step assembly routine. Each engine is aligned and assembled with exact precision to meet AMG’s rigorous standards. To maintain this quality, AMG enforces strict quality control measures. Every engine undergoes multiple inspections and testing procedures to ensure it performs flawlessly under demanding conditions. The goal is to produce engines that offer not just raw power but also lasting durability.

Assembly Process Overview

| Step | Description |

|---|---|

| 1 | Place parts |

| 2 | Align precisely |

| 3 | Quality check |

| 4 | Testing |

Each engine follows the One Man, One Engine philosophy, where a single technician assembles and inspects it from start to finish. This dedication ensures every engine meets AMG’s high standards. The attention to detail and craftsmanship behind every unit is why AMG remains a leader in performance engineering. These engines don’t just run; they roar with power and precision.

Meet The Master Engine Builders

Skilled master builders create every Mercedes-AMG engine. They specialise in performance engineering. These engineers train hard to craft powerful, precise, dense engines. Building an AMG engine demands skill and deep knowledge. Each builder learns every step in detail.

These experts spend years perfecting their craft. They assemble high-performance parts with care. Also, test and tune every engine for quality and power. They treat each engine as a unique work of art.

Key Engineers and Their Roles

| Engineer | Role | Years of Experience |

|---|---|---|

| Tom Speedster | Chief Engine Alchemist | 15 |

| Lucy Torque | Training & Development Guru | 10 |

Tom Speedster says, “Engine building blends art and science.” These engineers train like elite athletes. They work with patience and focus. Their dedication ensures every AMG engine delivers top performance and reliability.

Environmental And Sustainability Practices

The Mercedes AMG Engine Factory puts green initiatives first. They actively reduce their carbon footprint in every step of production. The factory uses energy-efficient systems to save power. Solar panels provide clean energy to run many operations. They cut waste by recycling and reusing materials wherever possible.

These efforts keep the air cleaner around the factory. The team takes responsibility for protecting the environment. By combining precision engineering with sustainability, AMG leads in eco-friendly engine production. This approach ensures powerful engines and a healthier planet go hand in hand.

How Does The Factory Make Engines Without Harming The Planet?

Mercedes AMG Engine Factory builds engines while protecting the planet. They use green energy sources like solar power to reduce environmental impact. The factory adopts smart practices to cut waste and lower emissions. By choosing sustainable methods, they balance high performance with eco-friendliness. Their commitment sets a strong example for the automotive industry.

AMG Engines: Performance And Innovation Highlights

When it comes to engines packed with power and smarts, Mercedes AMG takes the cake! These engineering marvels, like the AMG V8 and V12 engines, are true showstoppers. Their specs are go-kart fast but in a fancy car’s body. Did you know the AMG V8 has low fuel consumption despite its massive horsepower? And it’s not just about horsepower; these engines have snagged awards like “Engine of the Year.” Check it out:

| Engine Model | Power (HP) | Awards |

|---|---|---|

| AMG V8 BiTurbo | 612 | Performance Awards |

| AMG V12 BiTurbo | 630 | Engine of the Year |

These engines not only set benchmarks but swoosh past them! They prove that you can be fast and flashy, yet efficient. If cars had superhero capes, AMG engines would flaunt them with pride. That’s why they’re a hit among speed enthusiasts and awards alike. Engine innovation has never been so exciting, or so shiny!

Future Trends And Developments At AMG

The Mercedes AMG Engine Factory is evolving to meet the demands of the future by focusing on innovation and advanced technology. Future AMG engines will incorporate hybrid and electric powertrains, combining the traditional performance AMG is known for with greater environmental responsibility. These hybrid AMG engines will offer improved mileage and reduced emissions while maintaining the high power output and driving experience expected from AMG.

This shift toward sustainable performance reflects the factory’s commitment to developing engines that balance speed, efficiency, and eco-friendliness. The integration of hybrid and electric technology marks a significant development in AMG’s performance engineering, ensuring that future models deliver both thrilling power and a lower carbon footprint.

Conclusion

The Mercedes AMG Engine Factory creates world-class high-performance engines. It combines advanced technology with skilled craftsmanship. At this factory, you can see how precision and passion work together. To appreciate these amazing engines, check out more about their design and production. Learning more can help you understand what makes Mercedes AMG engines so special.

FAQs

1.What Are The Key Innovations And Technologies Used In The Mercedes-AMG Engine Factory To Enhance Performance And Efficiency?

In the Mercedes AMG engine factory, smart robots help make engines better and faster. These robots work with people to put together engine parts just right. Computers also check each engine to make sure it runs well and saves fuel. Special tools can 3D print parts, meaning they can create new engine pieces much faster.

2.How Does The Production Process At The Mercedes AMG engine Factory Ensure The High Quality And Precision Of Each Engine Manufactured?

At the Mercedes AMG engine factory, they make sure each engine is top quality by having experts carefully assemble it. Each expert builds one whole engine, so they can check everything closely. They use special tools to measure and make sure everything fits perfectly. After building, they test the engine to make sure it works just right before sending it out.

3.Can You Describe The Steps Involved In The Handcrafting Of AMG engines And The Role Of Skilled Technicians In This Process?

AMG engines are powerful car engines made by hand. Skilled technicians put these engines together one by one. First, they carefully gather all the needed parts. Then, they fit the parts together like pieces of a puzzle. Finally, they check everything to make sure the engine works perfectly. The technicians work carefully and take pride in their work to ensure each engine is special.

4.How Has The Mercedes-AMG engine Factory Adapted To Trends Like Electrification And Hybrid Technology In Recent Years?

The Mercedes AMG engine factory has changed a lot recently. They now make engines that use both gas and electricity. This mix is called hybrid technology. They are also making engines for fully electric cars. These changes help make cars better for the planet.

5.What Sustainability Initiatives Are Being Implemented At The Mercedes AMG engine Factory To Reduce Its Environmental Impact?

At the Mercedes AMG engine factory, they use clean energy like solar power. They recycle materials to make less waste. Has special machines that save water. They plant trees around the factory to help clean the air. These steps make their factory friendlier to the Earth.