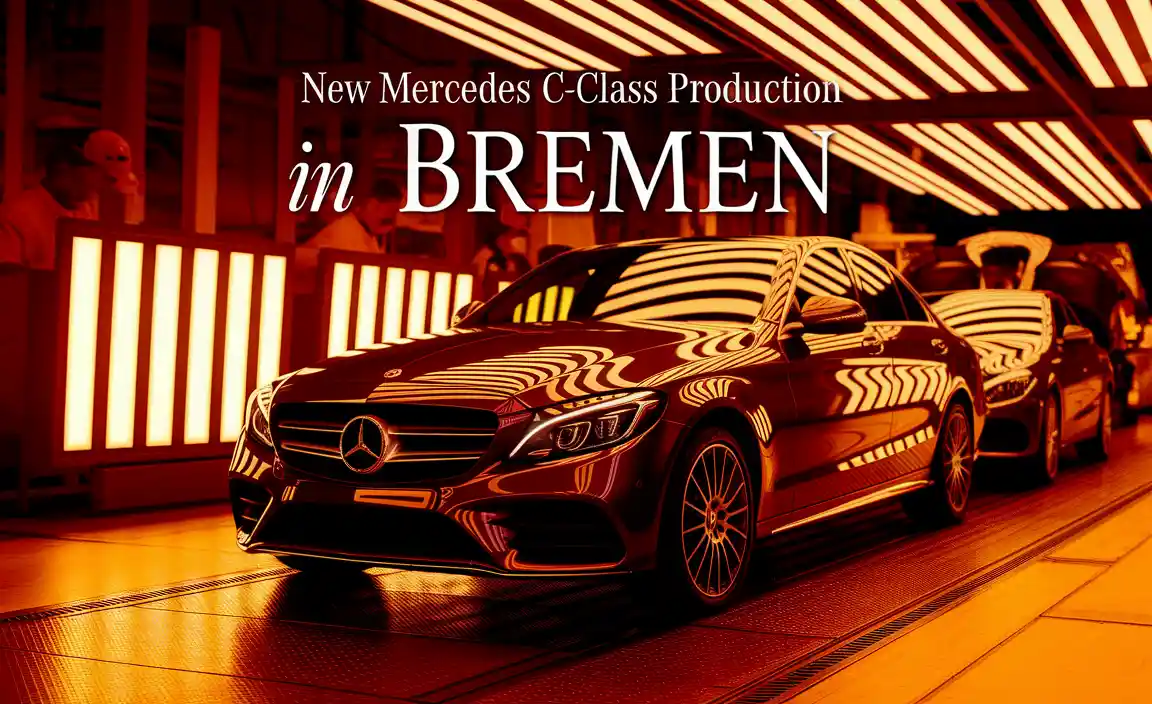

The new C-Class is officially rolling off the Mercedes-Benz Bremen Plant assembly lines. This marks a major milestone for Mercedes-Benz Cars. The company moves full steam ahead with the ongoing series production of one of its most iconic models.

With a strong heritage behind it and innovation ahead. The new C-Class production in Bremen represents a blend of tradition and future-ready engineering from the German automaker. The Bremen plant stands as a symbol of precision and innovation in automotive production. It plays a crucial role in the global production network of Mercedes-Benz AG.

Supports the demand for Mercedes Benz cars worldwide. Beyond just the new C-Class, this plant is home to the assembly of various other models. Such as the sporty AMG GT, the versatile C-Class Estate, and even the elegant CLE-Class Cabriolet.

Start Of Production In Bremen Plant

Located in the heart of Germany, the Mercedes-Benz Bremen Plant has begun full series production of the C-Class Sedan, also known as the C-Class Saloon in some markets. It’s not just another model rolling out; it’s the start of a new chapter in the Mercedes-Benz model line, representing precision, flexibility, and modern technology.

The C-Class Estate will follow soon after, sharing the same production line with other models like the Mercedes GLC and GLC Coupé, showcasing the maximum flexibility of the plant’s assembly systems. This integrated production setup reflects improved flexibility and the ability to adapt quickly within the global production network.

History And Legacy Of The Bremen Plant

Bremen’s story began decades ago, blossoming into one of the company’s most advanced production hubs. Its legacy is deeply entwined with the evolution of the Mercedes-Benz model line, especially as the new C-Class has become a flagship sedan representing the brand’s future.

Over the years, the plant has embraced many waves of innovation—from classic combustion engine assembly to today’s sophisticated hybrid and electric vehicle production. The bremen team has evolved with these changes, always ready to tackle new challenges while maintaining the high standards synonymous with Mercedes-Benz.

Cutting-Edge Production Process

To handle the new model, Mercedes invested in a new body shop at the Bremen facility. This upgrade supports a more modular and efficient production process, incorporating advanced production cells and optimized surface finishing techniques. As Markus Schäfer, Member of the Board of Management at Mercedes-Benz AG, stated, the goal is “to build outstanding vehicles with Mercedes quality at every stage.”

Inside the body shop, automation and human skill work hand in hand to ensure tight tolerances and sleek designs. The assembly line is also enhanced with technologies that reduce energy consumption and boost sustainability, aligning with Daimler AG’s green targets.

What’s unique about Bremen is its production quality and the maximum flexibility embedded in its processes. The plant efficiently juggles multiple production lines and models, thanks to its production cells and advanced assembly line systems.

Teamwork Behind The Scenes

It’s not just machines making magic happen. The Bremen team plays a central role. With experienced engineers and technicians, this team brings life to the C-Class Sedan and C-Class Estate with high levels of precision.

Andreas Kellermann, the site manager of the Mercedes-Benz Bremen Plant, praised the collaboration across departments and the spirit of innovation in every corner of the factory floor. “It’s not only a technical feat,” he said, “but a human one—driven by passion and expertise.”

Part Of A Bigger Picture

This launch in Bremen is part of the brand’s global production strategy. Other C-Class plants like the Sindelfingen Plant and Mercedes-Benz Vans facilities are also tuned into the rollout, ensuring uniformity and quality across continents. This synchronized production ramp-up enables a smooth and reliable delivery to markets worldwide.

The Mercedes-Benz model strategy aims to align classic combustion engine offerings with smart digital upgrades. New features like Dolby Atmos in the entertainment system show how tech is reshaping the cabin experience while retaining luxury DNA.

Quality Live – The New Benchmark

The company’s internal “Quality Live” system monitors every detail of the car during assembly. This includes digital tools to track production quality in real-time. These advances help maintain Mercedes quality while refining operational workflows.

A Home For Mercedes-Benz Model Excellence

Whether it’s the elegant E-Class Coupé, the dynamic C-Class Saloon, or rugged GLC Coupé, the company’s plant in Bremen continues to prove its versatility. The Mercedes plant supports global production goals while meeting local demands with unmatched quality.

With Daimler AG steering the future, the Bremen facility remains a symbol of innovation, quality, and commitment in the world of Mercedes-Benz cars.

Models Produced At Bremen

While the new C-Class grabs most of the spotlight, Bremen is home to a rich family of vehicles:

- The versatile C-Class Estate, perfect for families needing extra cargo space without compromising style.

- The CLE-Class Cabriolet, blending open-air freedom with Mercedes elegance.

- The fierce AMG GT, a true sports car born in this very plant.

- Select Mercedes-Benz Vans and SUVs, like the Mercedes GLC and GLC Coupé, also benefit from Bremen’s advanced manufacturing.

Economic Impact And Strategic Importance

Beyond cars, Bremen is an industrial heartbeat for the region. The plant’s operation means thousands of jobs, from assembly workers to engineers, supporting the local economy and reinforcing Bremen’s reputation as a critical industrial hub.

Strategically, Bremen’s location and its integration with the global production network give Mercedes-Benz an edge. Proximity to ports, efficient logistics, and a skilled labor pool strengthen the company’s competitiveness in Europe and worldwide.

Conclusion

To sum it up, the Mercedes-Benz Bremen plant is a remarkable blend of tradition and innovation. It carries the proud legacy of German automotive excellence while embracing the future with cutting-edge tech and sustainability.

When you see a new C-Class or a sleek AMG GT, remember it’s not just a car—it’s the product of a global production process finely tuned by the dedicated Bremen team, advanced technology, and a strong commitment to quality.

Bremen proves that behind every great car is a great place, where passion meets precision every single day.

Frequently Asked Questions

1.What Makes The Bremen Plant Important For Mercedes-Benz C-Class Production?

The Bremen plant is the lead facility for the new C-Class, responsible for setting production standards and integrating global manufacturing processes for consistent quality worldwide.

2.Which Mercedes-Benz Models Are Produced At The Bremen Plant?

Besides the new C-Class sedan and estate, Bremen produces the CLE-Class Cabriolet, AMG GT sports car, and key SUVs like the Mercedes GLC and GLC Coupé.

3.How Does The Bremen Plant Contribute To Mercedes-Benz’s Sustainability Goals?

Bremen incorporates environmentally conscious practices such as renewable energy use, waste reduction, and efficient energy consumption aligned with Daimler AG’s sustainability initiatives.

4.What Innovative Technologies Are Used In Bremen’s Production Process?

The plant employs automation, laser welding, advanced robotics, and a Quality Live system for real-time quality control to ensure precision and efficiency.

5.How Flexible Is The Production Line At The Bremen Plant?

Bremen uses modular production cells and smart assembly lines allowing maximum flexibility to switch between different models and ramp up production based on global demand.

6.What Workforce Training Programs Support Bremen’s Production Quality?

Extensive apprenticeship initiatives and continuous training ensure the skilled Bremen team maintains high craftsmanship and adapts to evolving manufacturing technologies.

7.How Does Bremen’s Location Benefit Mercedes-Benz’s Global Production Network?

Bremen’s strategic location near major ports and transport hubs facilitates efficient logistics and supports Mercedes-Benz’s worldwide supply chain and distribution.

8.What Role Does The Bremen Plant Play In Mercedes-Benz’s Global Competitiveness?

By leading C-Class production and innovating manufacturing processes, Bremen strengthens Mercedes-Benz’s position in the luxury car market with superior product quality and flexibility.

9.How Does The Bremen Plant Maintain Production Quality Across Different Mercedes-Benz Models?

Quality Live monitoring, precision surface finishing, and advanced assembly techniques ensure all vehicles meet the brand’s stringent standards.

10.Is The Bremen Plant Involved In Producing Electric Or Hybrid Mercedes-Benz Models?

While primarily focused on combustion engine models, Bremen is adapting to future needs with technologies and production methods that support Mercedes-Benz’s electrification strategies.