Imagine you’re walking into a Mercedes-Benz showroom, eyeing that sleek S-Class or the high-performance AMG model. You’ve saved up for it, but then- bam! The price has gone up.

Why? One major reason: raw material costs are soaring, and luxury automakers like Mercedes-Benz are feeling the heat. Mercedes-Benz Group AG, one of the world’s top luxury automakers, is grappling with the impact of rising material costs. From steel and aluminum to lithium for electric vehicle (EV) batteries, everything is getting more expensive.

Geopolitical tensions, supply chain disruptions, and inflationary pressures are making things even more challenging for manufacturers worldwide, including European carmakers like Mercedes-Benz and rivals such as General Motors and Tata Motors.

So, what’s going on? How is Mercedes-Benz AG managing these rising costs while maintaining its market share? Let’s break it down.

Key Takeaways

- Rising raw material costs are increasing Mercedes-Benz’s production expenses, impacting pricing and profitability.

- Steel, aluminum, lithium, and nickel prices have surged due to geopolitical tensions, supply chain disruptions, and inflationary pressures.

- Mercedes-Benz is mitigating costs through price increases, high-margin models, supply chain optimization, and sustainability efforts.

- Consumer behavior is shifting, with luxury buyers absorbing price hikes while budget-conscious buyers explore alternatives.

- The future outlook suggests potential stabilization of raw material costs, rising EV sales, and increased demand for fuel-efficient models.

Factors Contributing To Rising Raw Material Prices

Rising raw material costs in the automotive industry stem from supply chain disruptions, geopolitical tensions, and inflationary pressures. Key materials like steel, aluminum, and lithium have surged in price, increasing manufacturing costs for Mercedes-Benz Group AG and other automakers.

1. Global Economic Trends & Inflation

The automotive industry is heavily influenced by global economic shifts. Inflation, supply chain disruptions, and fluctuating crude oil prices all drive up production costs. The pandemic and geopolitical issues have worsened inflationary pressures, making raw materials more expensive.

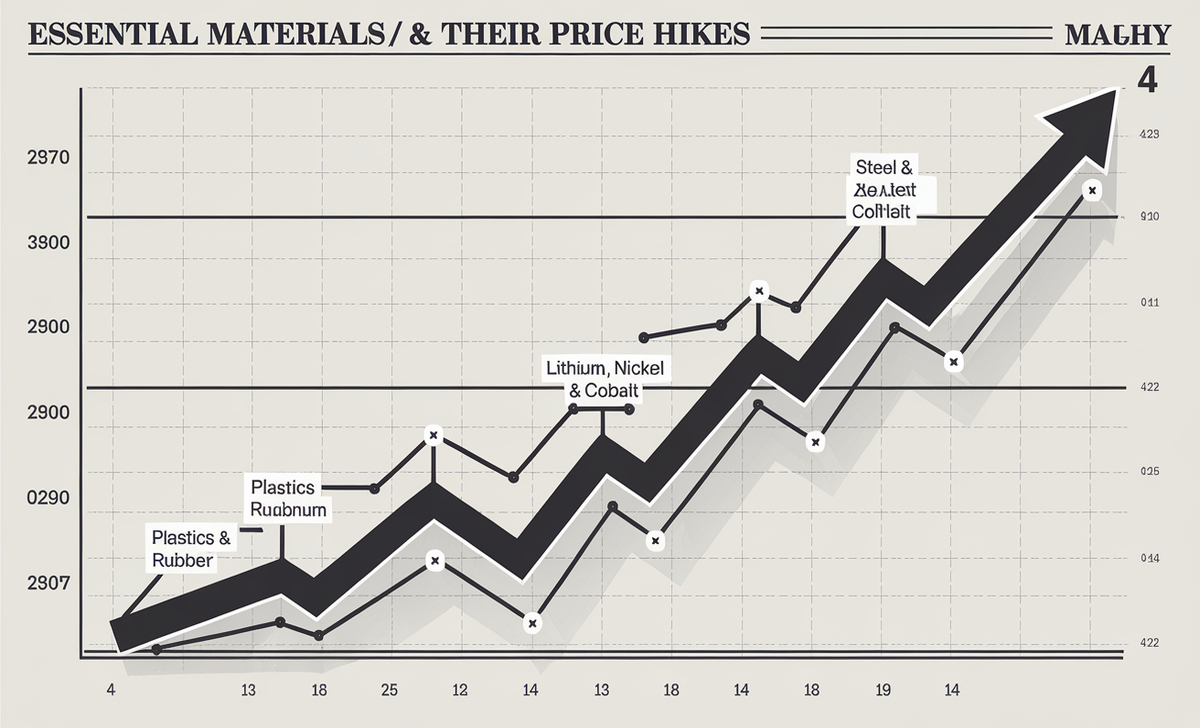

2. Essential Materials & Their Price Hikes

Mercedes-Benz depends on a range of materials, and many of them have seen dramatic cost increases:

- Steel & Aluminum: Crucial for vehicle frames, these metals have surged in price due to supply chain disruptions.

- Lithium, Nickel & Cobalt: Essential for EV batteries, their prices have skyrocketed due to increasing EV sales and limited mining capacity.

- Plastics & Rubber: Used in interiors and tires, these materials have also become costlier due to crude oil price fluctuations.

3. Geopolitical Tensions & Tariffs

Trade conflicts, especially between China, the U.S., and Europe, have led to higher tariffs, making imported raw materials more expensive. The ongoing Russia- Ukraine war has disrupted the supply of essential automotive materials like palladium, which is used in catalytic converters.

Impact On Mercedes-Benz’s Production Costs

The rising raw material prices have hit Mercedes-Benz’s manufacturing costs hard. Let’s compare:

- Pre-2020: Material costs were stable, and supply chain issues were minimal.

- 2021-2023: Raw material prices surged, and supply chain disruptions led to increased fixed costs.

- 2024 & Beyond: Mercedes-Benz Financial Services reports indicate further cost hikes, affecting net profit margins.

With higher input costs, Mercedes-Benz Vans and Mercedes-Benz Mobility divisions are also experiencing cost pressures. Even their commercial vehicle sector is seeing rising production costs.

Strategies Implemented By Mercedes-Benz To Mitigate Costs

So, how is Mercedes-Benz adapting? Here are some key strategies:

1. Price Increases On New Cars

Mercedes-Benz has raised the prices of several models, including luxury vehicles like the Maybach and performance models under the AMG brand. This helps offset rising material costs while maintaining profitability.

2. Focusing On High-Margin Models

Instead of mass-market vehicles, Mercedes-Benz is doubling down on high-end models where price hikes are more acceptable. Luxury goods consumers are less price-sensitive, making this a smart move.

3. Sustainability & Renewable Energy

To counter rising fuel efficiency concerns and CO2 emissions regulations, Mercedes-Benz is investing in sustainable practices like renewable energy sources and recyclable materials.

4. Supply Chain Optimization

The company is working to secure stable raw material supplies by forming partnerships with Chinese manufacturers and European suppliers to reduce dependency on volatile markets.

Consumer Response And Market Implications

The rising production costs at Mercedes-Benz have had a noticeable impact on consumer behavior. While some loyal customers remain committed to the brand despite price hikes, others are re-evaluating their options. Luxury car buyers often prioritize brand prestige, advanced technology, and high-quality craftsmanship, making them more likely to absorb price increases.

However, budget-conscious buyers, who previously aspired to own a Mercedes-Benz, may now consider more affordable alternatives. Additionally, electric vehicle (EV) buyers are closely monitoring market trends, waiting for material costs to stabilize before making their next purchase.

- Loyal Mercedes-Benz buyers: Prioritize brand prestige and quality, accepting the higher costs.

- Budget-conscious buyers: Considering alternatives like Maruti Suzuki and Tata Motors.

- EV buyers: Holding off on purchases, anticipating future price adjustments.

- Competitor response: Companies like General Motors are also adjusting prices, increasing market competition.

Future Outlook

Looking ahead, the automotive industry is expected to undergo significant changes as raw material prices, supply chain dynamics, and consumer preferences evolve. While material costs have surged in recent years due to supply chain disruptions and geopolitical tensions, there is hope that prices may stabilize as global trade normalizes.

At the same time, the demand for electric vehicles (EVs) is set to grow, pushing automakers like Mercedes-Benz to secure key materials such as lithium and nickel for battery production. Additionally, rising fuel costs and inflationary pressures may encourage consumers to prioritize fuel-efficient and hybrid models, reshaping the market landscape.

- Raw material prices may stabilize: Supply chain improvements could lead to more predictable costs.

- EV sales will continue to rise: Increased demand for lithium and nickel as Mercedes-Benz expands its electric lineup.

- Consumer preferences will shift: More buyers may choose fuel-efficient or hybrid models to offset rising costs.

Conclusion

The automotive sector is facing one of its biggest financial challenges yet. Rising raw material prices are increasing manufacturing costs, forcing Mercedes-Benz AG to adjust its pricing and strategy. But with innovation, supply chain improvements, and a focus on sustainability, Mercedes-Benz is positioning itself for long-term resilience.

FAQs

1.Why Are Raw Material Prices Rising In The Automotive Industry?

The automotive industry is facing a raw material cost surge due to geopolitical tensions, supply chain disruptions, and increased tariffs, making it more expensive for manufacturers like Mercedes-Benz Group to produce vehicles.

2.How Much Have Mercedes-Benz Prices Increased?

The price increase varies across models, with some Mercedes-Benz Cars and Mercedes-Benz Vans seeing hikes of thousands of dollars as the company adjusts for rising raw material expenses.

3.Is Mercedes-Benz Shifting To More EV Production Due To Material Costs?

Yes, Mercedes-Benz AG is expanding its EV lineup, but high raw material costs, especially for lithium and nickel, create challenges in scaling Mercedes-Benz Mobility offerings.

4.Will Car Prices Continue To Rise In 2024?

Possibly. If geopolitical tensions persist and raw material prices remain high, further price increases could affect both Mercedes-Benz Group AG and the broader automotive industry.

5.What Is Mercedes-Benz Doing To Manage Rising Costs?

The company is balancing manufacturing costs by optimizing its supply chain, adjusting vehicle prices, and focusing on high-margin models under the Mercedes-Benz Financial Services strategy.

6.How Does Rising Material Costs Affect Mercedes-Benz’s Market Share?

While Mercedes-Benz Cars remain dominant in the luxury automotive industry, some price-sensitive customers may shift to competitors, influencing the market presence of Mercedes-Benz AG.