When a vehicle encounters a starting disabled service throttle instance, it indicates a critical issue within the throttle control system that hampers its normal operation.

This malfunction can stem from various factors, such as a faulty throttle plate, sensor malfunction, or electronic control unit (ECU) error. Symptoms may include the inability to start the engine, the presence of warning lights like the check engine light or traction control light, and potential loss of power or response.

Proper diagnosis and prompt action are essential to address this issue, potentially involving diagnostics, sensor replacement, throttle body cleaning, or ECU resets. Additionally, verifying the integrity of the battery and related electrical components is crucial in resolving the starting disabled service throttle scenario.

Here, we will discuss the causes of SDST and provide step-by-step instructions on troubleshooting and resolving this issue. So, let’s dive in and discover how to tackle this frustrating problem easily and efficiently.

Key Takeaways:

- A disabled service throttle indicates a critical issue in the throttle control system.

- Causes include faulty sensors, damaged components, or ECU errors.

- Symptoms: difficulty starting, warning lights, power loss.

- Fixes: diagnostic checks, throttle body cleaning, sensor replacement, ECU reset, wiring inspection.

- Regular maintenance ensures long-term performance and prevents issues.

Reasons For Disabled Service Throttle

A disabled service throttle in a car can arise due to various underlying issues within the vehicle’s throttle control system. This malfunction can stem from a faulty throttle position sensor, damaged body, or corroded wiring connections.

Malfunctions in the electronic control unit (ECU) or irregularities in battery voltage can also contribute to this problem. Additionally, issues with traction control or carbon buildup on the throttle plate can lead to a disabled service throttle scenario, impacting the vehicle’s performance and drivability.

Identifying and addressing the root cause of the disabled service throttle is essential to ensure the safe and efficient operation of the vehicle.

- Faulty throttle position sensor

- Damaged throttle body

- Corroded or loose wiring connections

- Malfunctioning electronic control unit (ECU)

- Carbon buildup on the throttle plate

- Erratic signal from the pedal position sensor

- Battery voltage irregularities

- Intermittent issues with the traction control system

5 Fixing Processes For Starting Disabled Service Throttle

Fixing a disabled service throttle in a car is crucial for several reasons. Firstly, a malfunctioning throttle can significantly affect the vehicle’s drivability and performance, potentially leading to unsafe driving conditions.

Addressing this issue promptly ensures the safety of the driver, passengers, and other road users. Moreover, resolving the disabled service throttle prevents potential damage to other engine components and systems, minimizing the risk of costly repairs.

A properly functioning throttle system also optimizes fuel efficiency and engine performance, enhancing the driving experience. Five key fixing processes can be employed to rectify this problem systematically and efficiently.

1.Diagnostic Check

The diagnostic check is a fundamental step in fixing a starting disabled service throttle, involving specialized diagnostic tools to pinpoint the underlying issue.

This process includes scanning the vehicle’s onboard computer system for error codes related to throttle position sensors, ignition switch, or other relevant components. By identifying specific fault codes, technicians can determine the root cause of the problem, such as a malfunctioning sensor or electrical issue.

Additionally, checking for symptoms like engine misfires or the vehicle going into limp mode provides further insight into the problem. Clear communication with the car owner about diagnostic findings and potential solutions is crucial for efficient and effective repair.

2.Throttle Body Cleaning

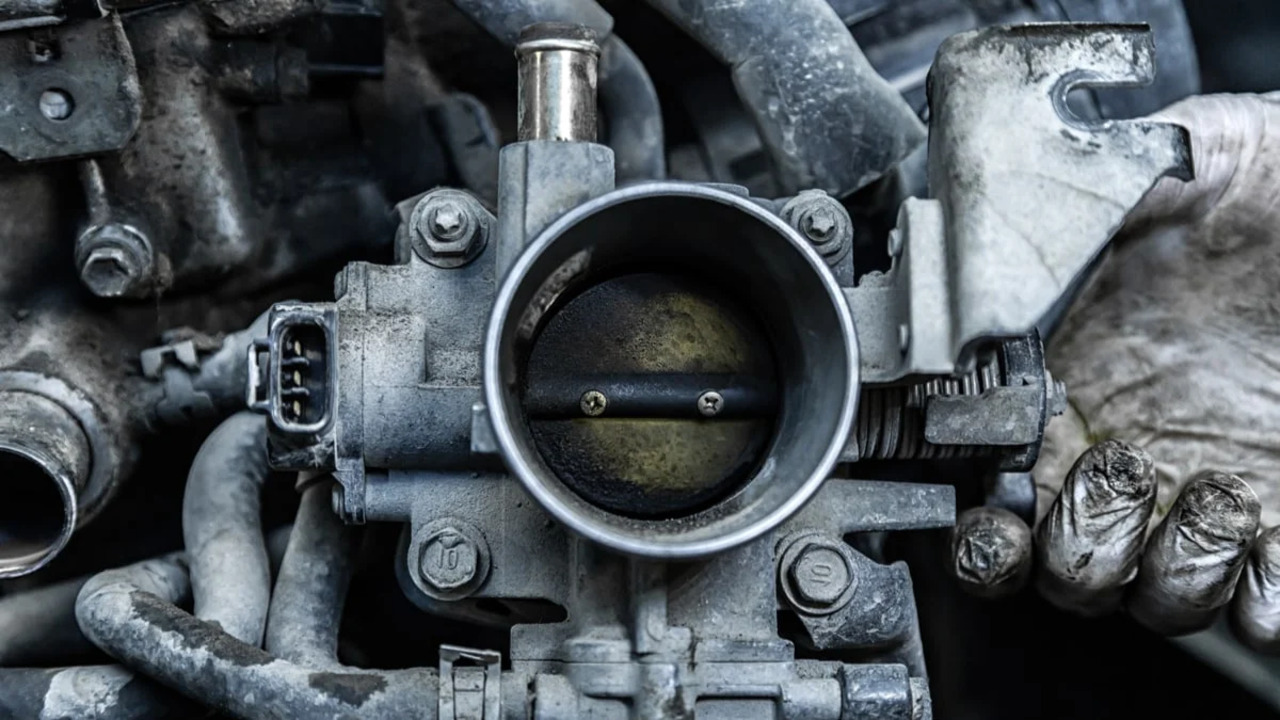

One essential fixing process for addressing a disabled service throttle is throttle body cleaning. This involves removing the throttle body from the engine for thorough cleaning using appropriate cleaners to eliminate carbon deposits and debris that can obstruct airflow.

Ensuring proper reinstallation and calibration of the throttle body is crucial to maintain optimal engine performance. Throttle body cleaning can resolve erratic throttle response or engine stalling, providing a cost-effective solution compared to component replacement.

Additionally, inspecting other engine components like spark plugs, wiring harnesses, and tires is advisable, as similar problems may arise from related issues. Seeking technical discussion or professional guidance can help diagnose and address the root cause of the disabled service throttle effectively.

3.Sensor Replacement

One crucial fixing process for addressing a starting disabled service throttle is sensor replacement. This involves identifying faulty throttle position sensors or other related sensors that may be causing the issue.

Once identified, the defective sensors are removed and replaced with new ones compatible with the vehicle, ensuring proper fit and functionality. After installation, calibration and testing of the new sensors are performed to ensure they operate correctly.

This process helps rectify any default in sensor performance that may trigger error messages or warning lights, restoring optimal throttle control and overall functionality to vehicles like Chevrolet.

4.Electronic Control Unit (ECU) Reset

One of the fixing processes for starting a disabled service throttle involves performing an Electronic Control Unit (ECU) reset. This procedure is essential for clearing any stored error codes or adaptive memory within the ECU.

Resetting the ECU allows for a fresh start and potentially resolves any issues that may have triggered the disabled service throttle. Additionally, the reset initiates a relearning procedure for throttle adaptation, ensuring optimal performance.

To fix this, disconnect the alternator and battery cables, wait for a few minutes, and reconnect them. This process effectively resets the ECU, enabling the vehicle to recalibrate its throttle system. Professional fleet services may offer ECU diagnostics and reset procedures for more complex issues.

5.Wiring And Connector Inspection

In the fixing processes for starting a disabled service throttle, thorough wiring and connector inspection play a crucial role. This involves meticulously checking wiring harnesses and connectors for any signs of damage, corrosion, or loose connections.

If any issues are identified, damaged wires and connectors must be promptly repaired or replaced. To fix this, carefully assess each wire and connector, ensuring proper insulation and secure connections.

Any damaged or corroded components should be repaired using appropriate techniques and replacement parts to restore the integrity of the throttle control system. This meticulous inspection and repair process ensures optimal electrical connectivity, minimizing the risk of further throttle-related issues and ensuring safe and reliable vehicle operation.

Maintenance For Long-Term Success

To ensure long-term success with your disabled service throttle for cars, it is important to prioritize regular maintenance. By following these maintenance tips, you can help prolong the lifespan of your disabled service throttle and ensure that it continues to provide reliable performance for years. Here are some key maintenance tasks to keep in mind:

- Clean and inspect the throttle regularly to remove any dirt or debris that may accumulate and affect its performance.

- Check the throttle cable for wear and tear and replace it if necessary.

- Lubricate the throttle mechanism to ensure smooth operation.

- Test the throttle response periodically to ensure it is functioning properly.

- Stay up-to-date with manufacturer recommendations or recalls for your specific disabled service throttle model.

Conclusion

Fixing the Starting Disabled Service Throttle requires a systematic approach. Assessing the scope of the issue and identifying the root causes are crucial first steps.

Once the causes are known, implementing the appropriate fixing processes, such as performance optimization, resource allocation, load balancing, error handling, and monitoring, is essential. Testing and validating the fixes are important to ensure their effectiveness. Regular monitoring and maintenance are necessary for long-term success.

Finally, following best practices for preventing Disabled Service Throttle, such as implementing proper error handling and establishing monitoring and alerting systems, will help minimize this issue. By taking these steps, you can effectively address the Starting Disabled Service Throttle and optimize your system’s performance.

Frequently Asked Questions

1.How Do We Reset The Service Stabilitrak Light?

First, to reset the service Stabilitrak light, park the vehicle on a flat surface and turn off the engine. Disconnect the car battery’s negative terminal and wait for a few minutes.

Reconnect the battery terminal and start the engine. If the issue persists, consult the vehicle’s manual for specific reset instructions or seek professional assistance.

2.What Happens If You Disconnect The Throttle Position Sensor?

Disconnecting the throttle position sensor (TPS) can lead to various vehicle performance issues. Without input from the TPS, the engine control unit may struggle to regulate the throttle properly, resulting in erratic idling, poor acceleration, and potential stalling.

Additionally, it can trigger warning lights on the dashboard and cause the vehicle to enter a reduced power or limp mode for safety reasons.

3.What Is AWS Database Migration Service?

The AWS Database Migration Service (DMS) is fully managed provided by Amazon Web Services (AWS) that enables seamless and secure migration of databases to AWS cloud infrastructure.

It supports various database engines, including MySQL, PostgreSQL, Oracle, SQL Server, and more, allowing organizations to efficiently migrate data with minimal downtime and ensure data integrity throughout the migration process.

4.What Causes Throttle Body Failure?

Throttle body failure can occur due to several factors, including accumulation of carbon deposits, wear and tear of internal components, electronic sensor malfunctions, or damage to wiring and connectors.

Contaminants entering the throttle body, such as dirt or oil, can also contribute to its deterioration over time, leading to impaired throttle response and engine performance. Regular maintenance and cleaning can help mitigate these issues.

5.What Does Starting Disabled Service Throttle Mean?

Starting disabled service throttle refers to a critical issue within a vehicle’s throttle control system that prevents the engine from starting or operating properly.

This malfunction can stem from various factors such as faulty sensors, damaged components, or electronic control unit errors, leading to warning lights, loss of power, and difficulty starting the engine. Addressing this issue promptly is essential for vehicle safety and performance.

6.What Are The Compliance Requirements For Starting Disabled Service Throttle?

Compliance requirements for starting disabled service throttle typically involve adherence to manufacturer specifications and industry standards. This includes conducting thorough diagnostic checks, following recommended repair procedures, and ensuring all replaced components meet OEM specifications.

Additionally, compliance may extend to regulatory requirements regarding vehicle safety and emissions standards, ensuring the vehicle operates within legal and environmental guidelines.

7.What Are The Potential Issues With Starting Disabled Service Throttle?

Potential issues with starting disabled service throttle include:

- Faulty throttle position sensor.

- Damaged throttle body.

- Corroded wiring connections.

- Malfunctioning electronic control unit (ECU).

- Carbon buildup on the throttle plate.

- Erratic pedal position sensor signal.

- Battery voltage irregularities.

- Traction control system malfunctions.